Technologies Applied in this Museum

Along with design that’s harmonious with the atmosphere of ancient Nara, we have put forth the technologies accumulated in our long history such as the Seismic Isolation System to reinforce security, and our air-conditioning system to offer a comfortable environment.

HARMONY

HARMONY

—Design and Construction Technology—

Designed to Promote

Designed to Promote

"Japanese Style"

Blending with

the Cityscape of Nara

We have designed the museum under the concept of harmony with the beautiful cityscape of ancient Nara.

Construction Technology

Construction Technology

for Exposed Concrete

To achieve a finer texture than that of ordinary exposed concrete, we applied formwork of cedar panels 35 to 60 mm wide and 12 mm and 15 mm thick, boarded up with plywood. With plenty of trials and testing, we paid careful attention to the management of cedar panels (pretreatment, moisture conditions and cross-section shape), solidity of concrete and the appropriate timing to remove the formwork.

Passing down the History

of the Former Nara Construction Office

This museum is built in place of Okumura Corporation’s former Nara Construction Office building, which had long been used as our management hub in Nara. The memory of the old building is carried on through the reuse of beams and roof tiles and the preservation of a cherry tree.

(from southwest)

(from northeast)

This museum is built in place of Okumura Corporation’s former Nara Construction Office building, which had long been used as our management hub in Nara. The memory of the old building is carried on through the reuse of beams and roof tiles and the preservation of a cherry tree.

bottom of the basin

without replanting it

from the Old Office as a decorative object

SECURITY

SECURITY

—Structural Design with

Seismic Isolation System and More—

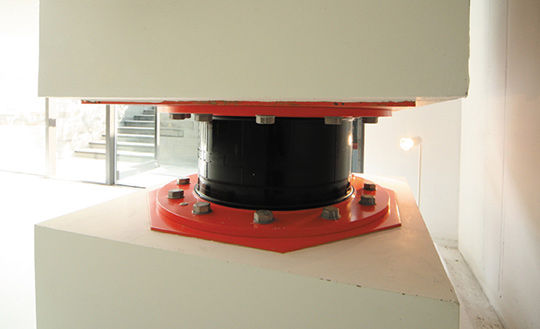

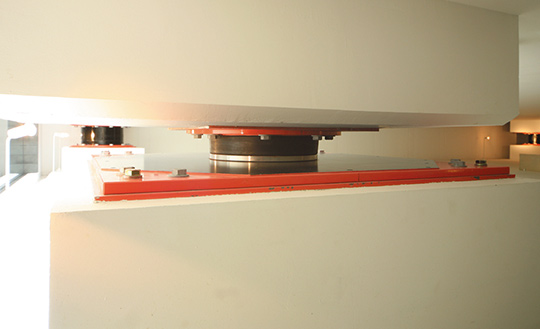

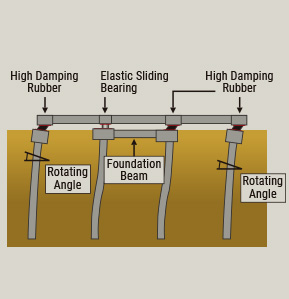

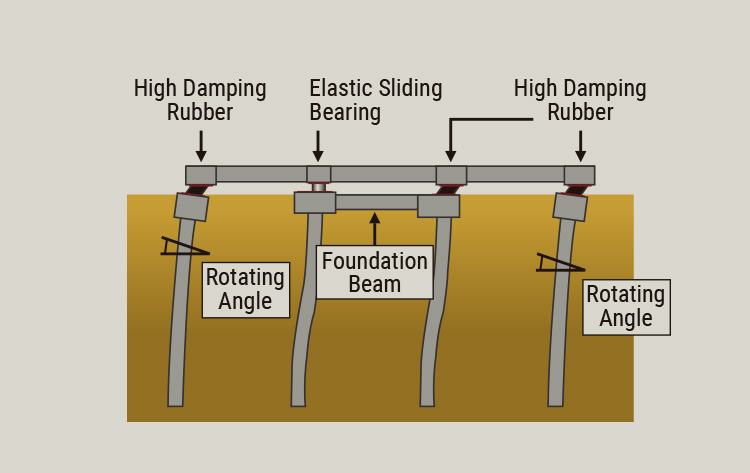

Seismic Isolation Structure Design Using

Seismic Isolation Structure Design Using

High Damping Rubber Bearings and Elastic Sliding Bearings

The combination of rubber bearings and elastic sliding bearings achieves long-term seismic isolation.

This system is economically applicable to relatively light-weight buildings. High damping rubber bearings display resilience and damping capability in the rubber itself and make dampers unnecessary.

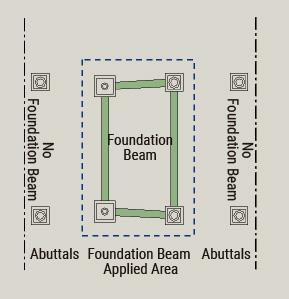

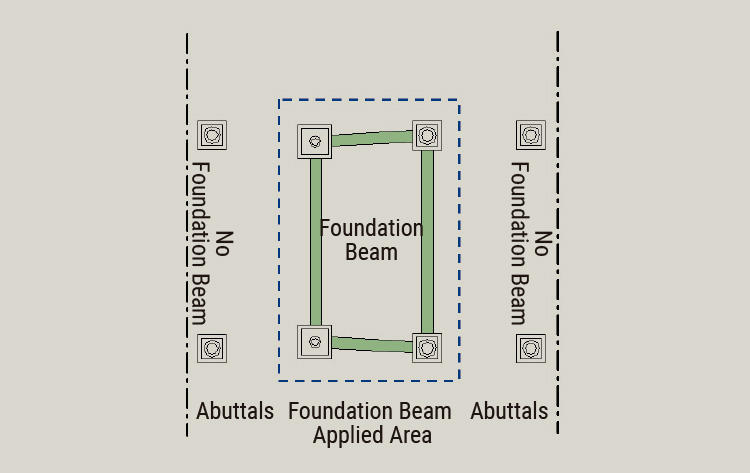

Construction Without

Construction Without

Foundation Beams Near Abuttals

This museum has applied no-foundation-beam construction near abuttals to avoid affecting the neighboring buildings, save soil-retaining and excavation labor, and reduce the cost. A minimum of foundation beams have been furnished against rotative force at the pile top in case of an earthquake.

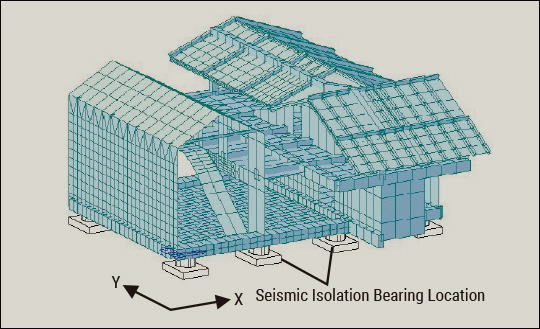

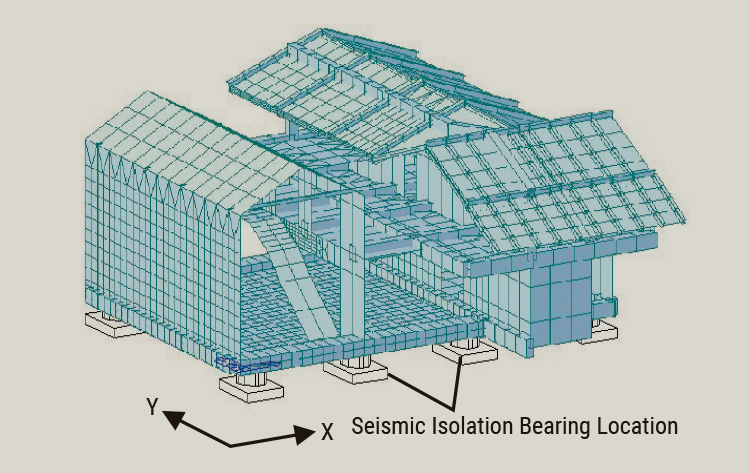

Downsizing of Seismic Isolation Pit

Downsizing of Seismic Isolation Pit

Using Hanging Structure

Size reduction of the seismic isolation pit area decreased the cost. This enabled hanging structures in some parts. Because the length from the hanging parts to the eaves is 6 meters, a hybrid structure of steel roof construction and RC pillars is applied to decrease the weight of hanging parts and control flexure.

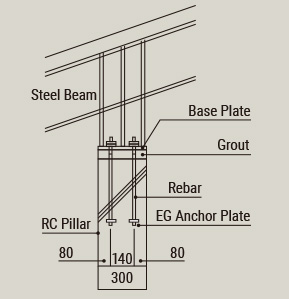

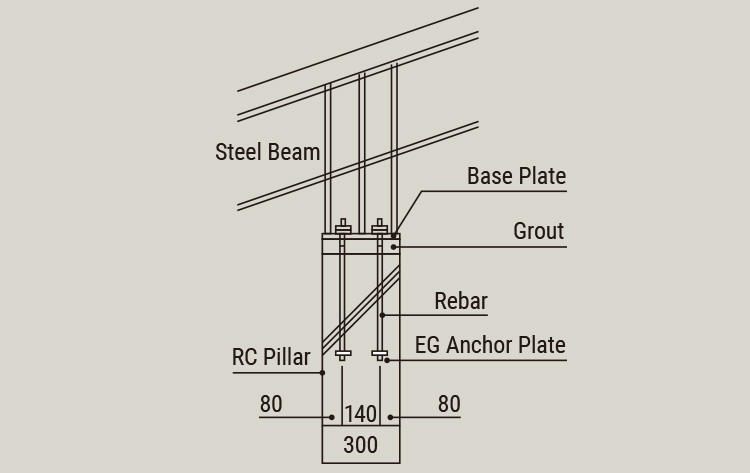

Joining RC Pillars and

Joining RC Pillars and

Steel Beams

by EG Anchor Plate Method

The EG Anchor Plate Method is applied to anchor rebar with round anchor plates screwed manually at the end of the rebar, and grouting is not necessary. In this museum, this method is applied to anchor bolts so that construction of narrow pillars becomes easy. This method refines the pillar-beam joint, simplifies the construction and reduces the cost.

Well-crafted Fitting

Well-crafted Fitting

We have provided a neat appearance on floors where seismic isolation and non-seismic isolation areas meet, and in the fitting of handrails, with refined design.

COMFORT

COMFORT

—Facility Design—

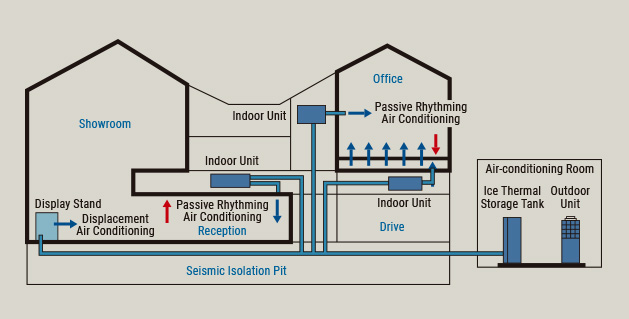

Effective Air Conditioning

Effective Air Conditioning

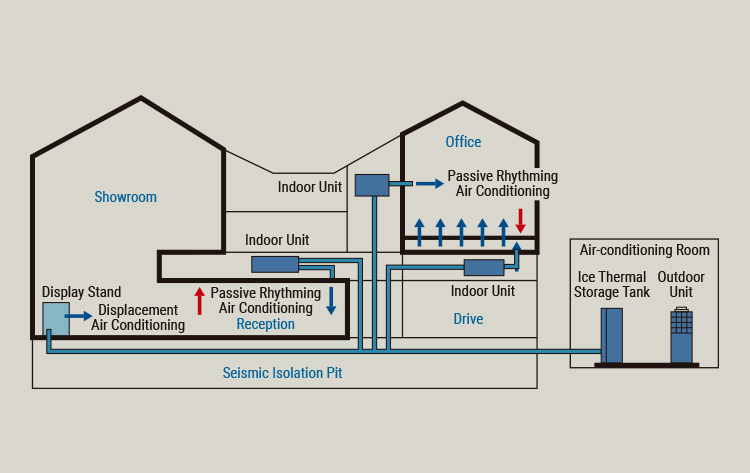

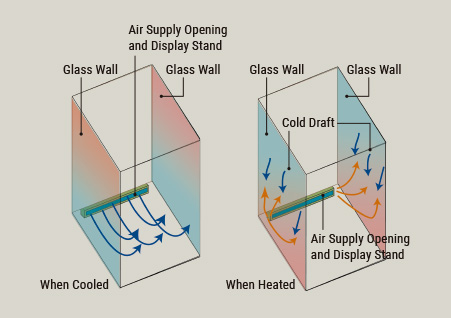

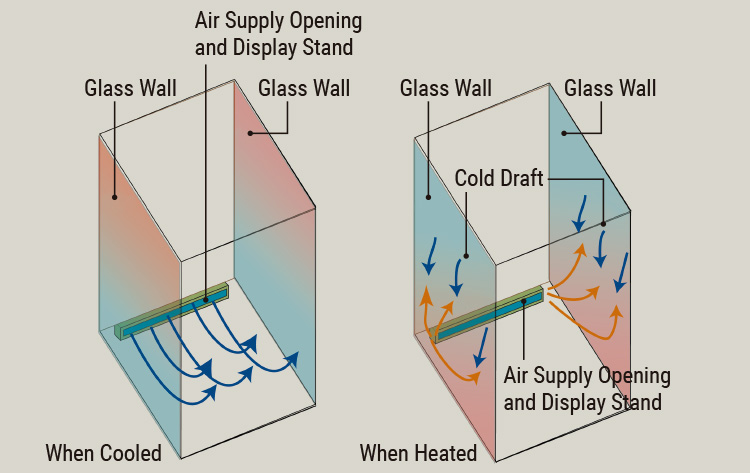

Displacement air-conditioning and a passive rhythming air-conditioning system are applied on the first floor to promote energy saving and comfort. Air flow direction can be switched during cooling or heating—especially in the two-story atrium—to enable quiet and mild air conditioning. The combination of ceiling-blowing-off and floor-blowing-off air-conditioning systems in the second-floor office increases comfort. The heat source is an ice thermal storage type air-conditioning system using electric power with late-night charges. This has enabled a low voltage power receiving system without installing cubicles. Air conditioner vents are concealed in the room for better design, and appropriate temperature distribution is planned using airflow analysis techniques.

![[Temperature Distribution Chart when Cooled] Simulation Results](/en/commemorative/img/technology/img_comfortable03.jpg)

![[Temperature Distribution Chart when Cooled] Simulation Results](/en/commemorative/img/technology/img_comfortable03_sp.jpg)

![[Sound Pressure Level] Simulation Results](/en/commemorative/img/technology/img_comfortable04.jpg)

![[Sound Pressure Level] Simulation Results](/en/commemorative/img/technology/img_comfortable04_sp.jpg)

Noise Control

Noise Control

in the Basement Machine Room

For noise control and design purposes, the ice thermal storage tank and the outdoor unit are installed in the basement machine room located underneath the archives. In order to control noise from machines, simulation using noise prediction plan technology was conducted, and the locations and the sizes of air inlets and outlets were decided according to the simulation results.