- HOME

- Technology

- Civil Engineering Technology

Technology

Civil Engineering

Technology

COPYRIGHT© Okumura Corporation. ALL RIGHTS RESERVED.

This is a shield tunnel rapid construction method, which carries out advancing and segment assembly simultaneously using a hexagonal Honeycomb Segment. Because the inner surface of the segment is smooth, a tunnel can be constructed without a secondary tunnel lining, allowing for a reduction in construction costs and shortening of construction schedule by the reduction of the digging diameter. The simultaneous operation makes shield tunneling in long distance much faster.

Highest Award of 3rd Infrastructure Technology Development Award (awarded by the Minister of Land, Infrastructure and Transport)

This is a no-dig construction method for underpass constructions. After taking on the orbital or road load with a rectangular steel tube attached with a friction-cut plate, it shoves the precast box culvert and replaces the steel tube with the box. It allows for a construction of a quality underpass with small earth covering. We have taken on over 250 experiences up till now.

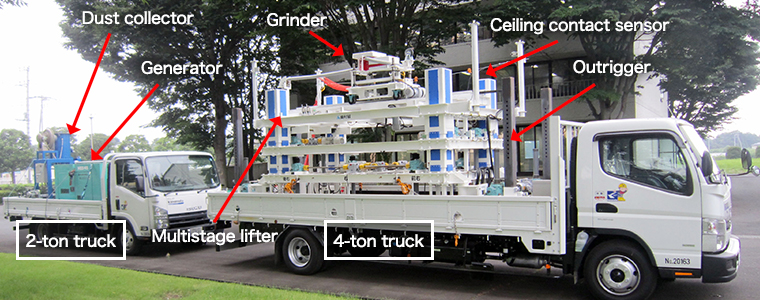

Photo-1 Truck-mounted dry ceiling grinder

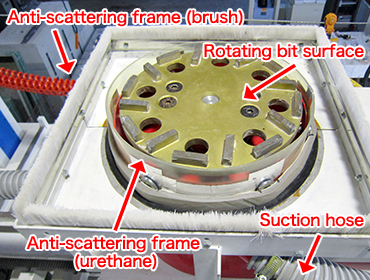

Photo-1 Truck-mounted dry ceiling grinder Photo-2 Grinder

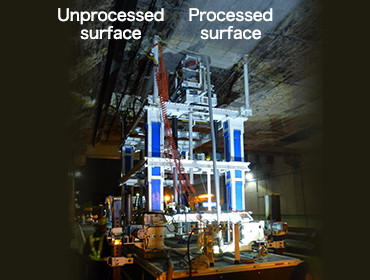

Photo-2 Grinder Photo-3 Implementation status

Photo-3 Implementation statusAs a preceding process to the repair and strengthening construction of a tunnel ceiling in service, this machine provides surface preparation, grinding grime or previous coating films off the concrete surface. The high-speed rotating bit of the grinder in the machine is pressed against the ceiling with controlled pressure and provides automatic surface preparation at a constant rate. The grinder is equipped with a double anti-scattering frame and suction device to prevent dust from scattering. This machine saves labor, and improves safety, quality, and uniformity compared to human labor.